How to perform effective installation of facade thermal insulation materials?

Adequate choice of fixing solutions and their proper application on the facade is a guarantee of the building’s thermal efficiency as well as of the insulation system’s stable operation against the destructive effect of weather conditions.

Rawlplug delivers a comprehensive system designed for installation of thermal insulation materials using the R-TFIX-8S-X screw-in facade fixings.

Insulation or comprehensive thermal upgrading of buildings are labour-intensive processes requiring highly specialised technical solutions. The choice of the right fixings is fundamental, but the key to efficiency is also correct installation. Rawlplug’s system of professional mechanical anchors intended for thermal insulation materials comprises three components that guarantee adequate installation: a wide range of the R-TFIX-8S-X facade fixings, setting tools, and thermal insulation caps.

R-TFIX-8S-X, or how to choose the right screw-in facade fixing?

The correct choice of fixings guarantees stable and exceptionally durable installation of facade insulation materials. The R-TFIX-8S-X is probably the most versatile screw-in facade fixing, and this pertains not only to the Polish construction market. Our screw-in fixing for thermal upgrading works is characterised by top performance, and it is suitable for virtually any substrate and any thermal insulation material, being particularly recommended for ETICS.

Why choose the R-TFIX-8S-X universal screw-in facade fixing?

There are diverse mechanical solutions available on the facade fixings market. The R-TFIX-8S-X screw-in fixing with a metal screw deserves your attention for several important technical and installation reasons:

- it is adapted to any chosen substrates and insulation materials;

- it offers excellent performance and the shortest minimum anchorage depth, reduced to 25 mm;

- the unique design of its anchoring zone makes it capable of transferring high loads and reduces the number of anchoring points required per square metre;

- featuring pre-assembled fixing components, the solution allows you to save time and makes installation less labour-intensive;

- high plate stiffness guarantees stability of the thermal insulation system under wind-induced pull-out forces.

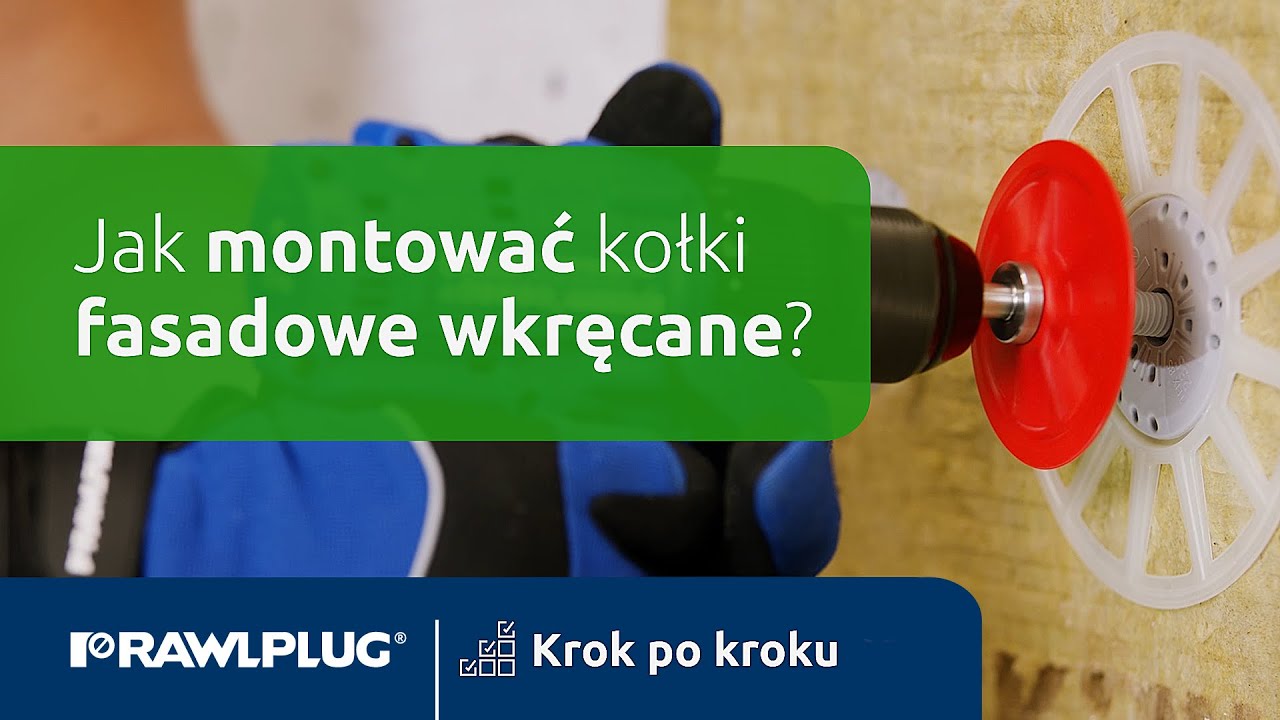

Facade fixings: how to install screw-in fixings easily and quickly in polystyrene and mineral wool?

How to perform countersunk installation of thermal insulation panels using Rawlplug’s screw-in facade fixings in the simplest and most efficient way? We always provide our customers with comprehensive solutions to ensure appropriate fixing, which is why we have the right answer – the new R-TFIX-TOOL-CSMP setting tool.

The innovative R-TFIX-TOOL-CSMP setting tool makes it possible to embed the facade fixing (anchor) in the most efficient and least invasive way possible, including preparation of a recess for countersunk installation. Its perforator is designed to avoid the additional need to cut the thermal insulation material.

Why use the R-TFIX-TOOL-CSMP when installing thermal insulation systems?

- The TX40 bit is perfectly matched with the screw socket, which facilitates stable fixing of polystyrene or mineral wool panels;

- the tool features a retaining plate with a diameter of 120 mm which prevents it from sinking into the thermal insulation material;

- the retaining plate eliminates the pull-through effect in the insulation material;

- the tool’s design prevents any imprints from being left on the insulation material, especially when fixing polystyrene panels;

- the tool makes it easier and faster to prepare the facade surface for the final finishing work.

Screw-in facade fixings: how to minimise thermal transmittance at the anchoring point?

How to get rid of the point thermal bridging effect? The last element of Rawlplug’s system used in the installation of facade thermal insulation materials is the thermal insulation cap (plug). Rawlplug delivers it in three variants: the R-TFIX-CAP63-EPS-W white polystyrene cap, the R-TFIX-CAP63-EPS-G grey polystyrene plug, and the R-TFIX-CAP63-MW mineral wool cap. The thermal insulation cap is a round disk whose dimensions match the size of the perforator-made hole. It is used to close the hole formed by installing the facade fixing.

When appropriately installed and blanked off using the thermal insulation caps, the fixings make it possible, in the first place, to reduce thermal transmittance at the anchoring point and to produce the desired uniform facade surface.

Complete fixing system for thermal insulation materials: installation guide

Thermal upgrading of buildings using Rawlplug’s fixing system is a quick and easy process. Setting of fixings and installation of insulation materials on the facade proceed in a few steps performed using essential tools.

You can also watch the correct installation of the facade fixings demonstrated in the Rawlplug Academy video on the YouTube channel of Rawlplug Polska. It will instruct you on how to install our screw-in facade fixings, use the setting tool, and complete the quick installation of thermal upgrading materials with our insulation caps.

Elements of Rawlplug’s professional fixing system for thermal insulation materials

Read more about the products comprising our fixing system:

Setting tool: R-TFIX-TOOL-CSMP

Metal screw-in facade fixing: R-TFIX-8S-X

Caps: R-TFIX-CAP63-EPS-W, R-TFIX-CAP63-EPS-G, R-TFIX-CAP63-MW

Related articles

16 July 2025

#EasyFix softwareModule: ETICS Facade – first steps

1 March 2025

#SiteTestingOn-site fastening test – R-FF1 frame fixings

23 December 2024

#SiteTestingSite fastening test - R-TFIX-8S polystyrene and wool fixings

4 November 2024

#FixingsTest on the construction site - fixings for polystyrene foam and wool KI-10M